Construction glue for boatbuilding?

Often it would be nice to be able to use a one component glue

directly from a caulking gun in a boatbuilding project.

The so called "construction glues" would seem

to offer this possibility. Usually they are claimed very strong,

waterproof, suitable for exterior use and, to some extent,

solvent tolerant.

The following is a simple "semi scientific" test I've carried

out on several brands of these glues.

|

First I glue two pieces of 12 mm (1/2") spruce plywood

together. The glued area is about 5 cm x 5 cm (2" x 2").

Then, I let the glue cure for a week in a warm, dry place.

After a week wild horses could hardly separate the pieces

of ply.

|

|

Then it's time for two day's soaking in ordinary tap

water.

|

|

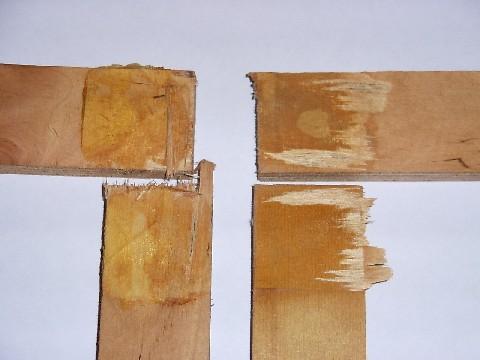

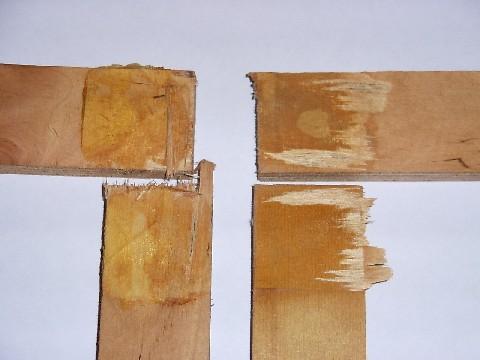

The proof of the pudding is in the eating. If I can separate

the plywood pieces by hand, the glue fails the test.

Here the glued area is clearly only about 1" x 1", but the failure

is obvious, all the same.

The failure mode can also be seen clearly: The glue simply

peels off the wet wood.

|

If a brand of glue passes this first phase, I'll subject it to the

boiling test described in Dave Gerr's book "The Elements of Boat Strength".

First the specimen is boiled for four hours. Then dried in 60 degrees

Centigrade for 20 hours. Then boiled again for four hours. Let cool

in water. Test for strength.

According to Gerr, if a glue passes the boiling test, it can be called

"waterproof".

|

My version of the boil test goes like this:

- Boil for four hours in the evening.

- Let dry in the sauna afterheat until the next evening.

- Boil again.

- Let cool in the water on the kitchen table until the next evening.

- Rip the plywood pieces apart.

This, of course, is not very scientific, no ripping force measurements, for

example. But definitely better than nothing!

|

Results by brand, so far

| Brand |

Soak test |

Boil test |

| Biltema Construction Glue |

Failed |

- |

| Casco SuperSet 3879 |

Passed |

(Passed) |

| Kiilto Masa |

Failed |

- |

| PL 400 |

Failed |

- |

| SikaBond 500 |

Failed |

- |

| SikaBond T2 |

Failed |

- |

| SikaFlex 11FC |

Passed |

Passed |

| SikaFlex 292 |

Passed |

Passed |

| Wurth glue/sealing compound |

Failed* |

-* |

| Rotabond 2000 |

Passed* |

Passed* |

| Tremflex HS |

Passed* |

Passed* |

| Other glues for reference |

| All B3 rated |

Failed |

- |

| Biltema Quick Epoxy |

Passed |

Passed |

| Lidl epoxy |

Passed* |

Passed* |

| West System 105 |

Passed* |

Passed* |

The tests marked with an asterisk (*) by my friend Veli-Matti Dahlgrenin.

In all cases of soak test failure the glue peeled off the wet wood.

And very easily indeed. The soak test failed glues have no place in wooden

boats.

Of the glues that have passed the test so far, the SikaFlex 292,

is specifically claimed suitable for boat use. Casco SuperSet and

SikaFlex 11FC are

general purpose glues. Biltema Quick Epoxy is similar to the better

known Araldite Rapid.

|

The samples after the boil test. From left to right: Casco SuperSet,

SikaFlex 292, Quick Epoxy.

The Casco SuperSet passes the boil test barely, I'd say. The plywood

pieces were hard to rip apart. The failure occurred mainly between wood

and glue, some wood was ripped off with the glue.

Wood clearly broke first with SikaFlex 292. The remaining glue could be

peeled off the wood with finger nails.

The same with Quick Epoxy. The remaining glue had turned rather soft.

|

|

SikaFlex 11FC sample after the boiling test. This one was a positive

surprise to me. Cheaper than SikaFlex 292 or Casco

SeperSet, but the hardest to rip apart after the boil test.

The first one I couldn't tear apart with bare hands. You can still

see the pipewrench marks on the lefthandside piece.

|

|

Rotabond 2000 after the boiling test.

Rotabond may be unknown to most boat builders. As far as I know, it

can only be obtained in boxes of twelve. Rotabond product line has

products corresponding to most products on the Sikaflex

product line.

(Picture and text by Veli-Matti)

|

|

Tremflex HS after the boiling test.

Rotabond and Tremflex were so strong that they could not be ripped apart

by hand. A big vice and a 24 oz. Real Timber hammer were needed. And I

had to hit like I'd hit a 4" nail, not like a 2 1/2" one.

(Picture and text by Veli-Matti)

|

|

Lidl epoxy (on the right) and West System (on the right) after the boiling test.

Rotabond 2000 ja Tremflex made a much stronger bond than the

West 105 and the cheap Lidlin epoxy glue.

Still, the epoxies did hold to the end.

(Picture and text by Veli-Matti)

|

The two interesting ones remaining to be tested are the 3M5200

and PL Concrete. Once I bump into them :-)

Top of the page.

Back to main page.