Plywood lath coracle

The history of the coracle

A coracle (sometimes written also as "corracle") is a small basket boat,

or a skin boat. A basket boat in the sense, that the frame of the

boat is traditionally made by bending and weaving wood saplings together like a basket.

Skin boat in the sense, that the basket is made waterproof by stretching

an animal skin over the basket.

Basket boats may be the oldest boat type. Or possibly second oldest,

after dugout canoes.

A well known written description of an ancient basket boat

can be found in the Bible, Exodus 2, where little Moses is left floating in the

river Nile by her mother:

But when she could hide him no longer, she got him a wicker basket

and covered it over with tar and pitch. Then she put the child into

it and set it among the reeds by the bank of the Nile.

The history of basket boats thus stretches thousands of years. In most

parts of the world wooden boats replaced basket boats in the course of

history.

It is understandable, that in many areas it has been more economic to use

skins for clothes, and wood for boats, as soon as woodworking tools have

become available.

Basket boats are still used in some locations. In Vietnam, India and Iraq,

probably.

The last places of skin boat use in Europe have been Wales, Ireland and Scotland.

In real fishing and ferrying use up to the beginning of the 20th century,

after that for pleasure use, and to foster the tradition.

Coracle is not a general name for a basket boat. Instead, it is the name of

the light, one person basket boats used on the small salmon rivers of

mainly Wales, but also Ireland and Scotland.

The nature of a coracle

A coracle typically seems to be 3' to 4' (90-120 cm) wide, 4' to 6'

(120-180 cm) long. Viewed from above, the shape of coracles varies.

Some are round, some oval, some quite square, with almost a flat

transom, some with sharpish bows.

Different rivers in Wales have their distinctly different coracle types.

The bottom of a coracle is straight and flat. There is no keel.

The frame of a coracle is traditionally made of willow or hazel saplings.

For a couple of last centuries the frames of some types

have been made of ash laths.

The skin material has been the hide of a cow, ox or a horse. From around

the 16th century different man-made fabrics, waterproofed with various

tar products, have replaced animal hides. First it was woolen fabrics waterproofed

with a mixture of tar and linseed oil, later cotton waterproofed with

bitumen paint, and in more recent times polyester or nylon, coated with

oil paint. A fabric coracle only weighs about half of a hide covered

coracle.

A plastic frame with a polytarp cover would probably classify as a coracle,

but isn't that a bit too modern? ;-)

The seat of a coracle is usually attached close to the gunwale. Relatively

high up, that is.

The propelling force of a coracle is a single-blade paddle. A boat that is

almost round cannot be paddled like a canoe (it would only spin around), but

the paddle stoke is either a "reach forward", or a "figure of eight", where the

paddle acts as a single propeller blade swinging from side to side.

The paddle is held in front of the boat, with the paddler facing in the direction

of travel.

A coracle is a dangerous boat:

- It is so small and light, that it is very tippy.

- A coracle has no keel, but the bottom is quite straight and flat. The

windage is relatively high, however. Thus a coracle will go "where the wind blows"

and also where the stream takes her.

- Coracle paddling is not very efficient. There is no guarantee of getting against

the wind nor upstream.

- If a coracle capsizes, there is no way to get back in, and it offers no

flotation.

- Although the skin or fabric cover is tougher than one might expect, it may

get pierced by sharp rocks.

- A coracle has very little floating material. A pierced coracle does not

float a swimmer.

- A coracle may flip forward, if the paddle gets stuck in weed or something else

submerged.

- People have drowned, when wind has caught a coracle being carried, and taken

people into water with the coracle.

So what on earth is the justification for existence of such a caricature of a boat?

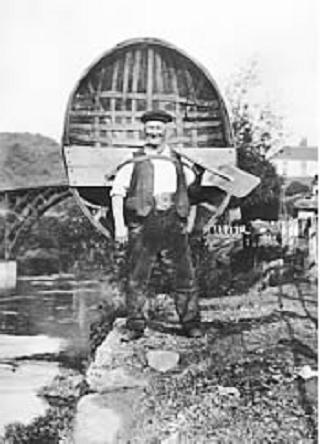

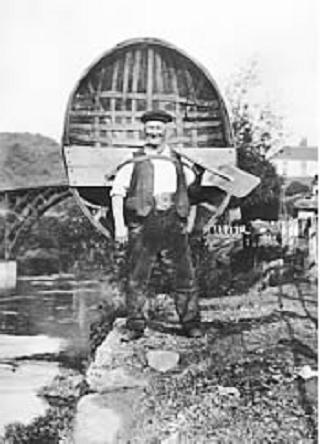

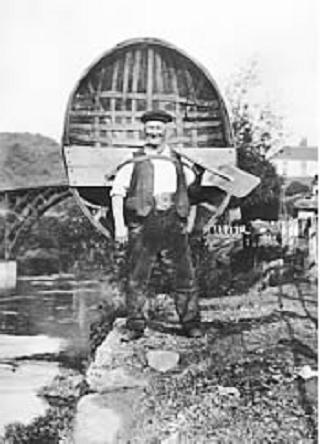

This picture of a "Welsh old boy" reveals it all.

|

A coracle is so small and light that it can be carried like a rucksack.

A leather strap attached to holes in the seat acts as a carrying harness.

The paddle may be user to help with balance.

A personal boat, that is. There is hardly another type of boat that would

be as easy and light to transport on solid ground.

The manner of carrying may explain the high placement of the seat. When the

seat is level with the gunwale, the edge of the gunwale will not press

against the lower back of the person carrying the boat.

The coracle pictured here is of the Severn-Ironbridge type. The village got

the name Ironbridge from

the first iron

bridge in the world, completed in 1779, across river Severn.

The bridge can be seen in the background on the left.

|

Severn coracle

A Severn-Ironbridge

coracle

seems to be around 3 1/2' (105 cm) wide, 4 1/2' (135 cm) long, oval in shape.

Its ash lath frame seems to consist of seven to nine lengthwise laths, and

seven to nine crosswise laths.

The seat is of spruce, some 8" in width, a little under 1" thick. And supported

from underneath by two or three vertical supports. And the seat is, strangely, attached

on top of the gunwale, as can clearly be seen in the picture.

Let's build one! Or at least something resembling a real Ironbridge coracle ;-)

Building a coracle

Let's build a coracle roughly like this:

- Modeled loosely as Severn-Ironbridge.

- Width about 3 1/2' (105 cm), length about 4 1/2' (135 cm), depth about 14" (35 cm).

- The oval of the gunwale modeled by eye. That's how they have been modeled for millennia.

- Nine laths lengthwise, nine laths crosswise.

- But instead of ash laths I'll use laths sawn out of 5/32" (4 mm) birch plywood (door skin).

- The width of a lath could be 1 3/8" (35 mm).

- The gunwale will be made by gluing layers of plywood laths together.

- The boat will be covered with cotton canvas.

- And waterproofed with bitumen paint.

- And one round of protective lath will be attached to the gunwale on the outside

of the canvas.

- But I'll fasten the seat, against tradition, level with the gunwale.

- The seat of spruce.

- Three vertical supports under the seat.

A sheet of plywood is first sawn into laths. 28 laths are needed, more than 30 can be sawn

out of a single sheet, so one sheet of plywood is plenty.

It makes sense to have the sheet sawn at the lumberyard with a good

circular saw. That way the laths will be straight and of constant width.

|

The actual building starts from the seat, however. A piece of planed spruce,

3 1/2' long, some 8" to 10" wide, and some 3/4" thick.

I made mine by gluing two 5" board together by the edges with epoxy.

|

|

A temporary plank or batten is attached on

the underside of the seat with small nails. In the middle sideways, and at right angles to

the seat. The batten is 4 1/2' long. The mid point of the batten is lined up with

the front edge of the seat. This batten will determine the length of the

coracle.

A piece of wood, the thickness of the seat, is nailed under the long end of

the batten to keep it level with the floor.

|

|

Two plywood laths are wrapper around the ends of the seat and the lengthwise batten.

This is the first, innermost layer of the gunwale. The laths are cut to such lengths,

that the ends land on the ends of the seat.

|

|

The ends of the laths are glued and nailed (or screwed) into the ends of the seat.

The seat and gunwaler are now upside down. When turned right side up the top

of the seat will be flush with the top of the gunwale.

|

|

A second and third layer of laths are wrapped on the first layer, glued to

previous layers, the ends of the laths are nailed to the ends of the seats again.

|

|

After the glue has hardened, the gunwale keeps its shape and the lengthwise batten

can be removed.

|

While the glue is hardening, we can continue with the bottom.

|

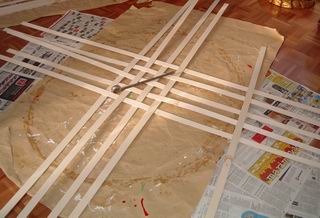

The coracle bottom is woven like a basket out of nine crosswise and nine

lengthwise laths. The weaving starts from the middle.

|

|

Weaving continues in all four directions in turns. The center to center

distance between laths is about 4" (100 mm), so the edge to edge distance

between adjacent laths is about 2 5/8" (65 mm).

|

|

The completed weaving is attached onto a straight bed of two lengths of

two by two. The batten that was used when making the gunwale is cut into two.

The two lengths are screwed through into the two by twos, to keep the

weaving flat and steady.

|

|

Three vertical supports are glued and screwed under the seat.

Supports can be round or square, 1" to 1 1/2" in diameter, and

made of some light wood. The length of the supports is 12" (30 cm).

The location of the supports is 4" (10 cm) back from the front edge of the seat.

The mid support is in the middle (of course), and the two others 8" (20 cm)

to either side.

|

|

When the seat-gunwale is positioned on top of the basket bottom and vertical

supports, the front edge of the seat comes directly above the middlemost

crosswise lath. The supports land on the next crosswise lath, the mid support

on the mid lengthwise lath, the others on the third and seventh lengthwise lath

(sounds a lot more complicated than it is ;-). The ends of the supports

are glued and screwed to the lath crossings.

Use a couple of lengths of batten to support the gunwale-ring horizontal

now. The sturdier the support, the easier the building from here on.

|

|

Start bending the laths to the gunwale. The laths are bent one by one, starting

from the lengthwise and crosswise mid lath, proceeding towards corners.

The laths can be attached to the gunwale using small screws. You may need to adjust

the laths, so don't make the attachment permanent yet.

The plywood laths don't bend to a tight enough curve as such, but heated with

a cheap 1500 W heat gun they become (almost ;-) cooked spaghetti.

|

|

No exact measurements can be given for the bends. Make them pleasing to Your

eye, that's all.

It is worth making the bends relatively sharp, however. In other words,

it is worth making the bottom a wide one. This way the coracle will

have higher displacement and stability.

When the basket looks good enough, the lath crossings can be fixed with small

blobs of glue, and the lath ends glued and screwed to the gunwale. Once the

glue is hard, the screws can be removed.

|

|

Every corner of the coracle will have an extra corner lath. Each corner lath

touches three crosswise and lengthwise lath crossings. Between the laths,

on the inside, and on the outside.

Once all glue is hard, the lath ends are cut along the top edge of the gunwale.

|

|

The coracle frame is now wood-ready. One more lath layer has been glued onto

the gunwale to cover the bottom lath ends.

At this point it makes sense to treat the frame against rot, impregnate it

with linseed oil, and possibly paint it. The most suitable color is natural

wood after the linseed treatment, or dark green.

My frame will just be painted with linseed oil twice. Painting it carefully

with a color paint

would take the best years of my life. Stored indoors away from sun and rain,

and used occasionally, it will last for years, if not decades.

|

|

The cover could be animal hide, cotton canvas, polyester or nylon, almost

any sturdy fabric-like material.

I went to the local fabric shop asking for a 5'8" x 6'8" (170 x 200 cm) piece

of some strong fabric.

"It'll be this cotton canvas. It's width is exactly the 5'8" You ask for.

Most fabrics are at most 4'8" (140 cm) wide, this is the only extra wide we have."

Great! By accident the measurements of my coracle coincide with the widest

fabric available!

"You won't wash it then, will You? It will shrink by some 8 %."

Even greater! I needs to shrink!

|

|

The fabric should be attached to the frame as tight and as wrinkleless as possible.

There's no need to overdo this, however. Old genuine coracles often seem to be nothing

but piles of wrinkles.

The result is probably neatest, if You double the edge of the fabric and staple it

to the outside of the gunwale rim. The staples should be stainless.

Here the canvas has been stapled to the gunwale in single thickness.

A traditional builder would, of course, not use staples, but twine or sinew...

|

|

The edge of the fabric cut short, then folded out to double thickness, and stapled

to the gunwale.

Next the fabric will be wetted, let dry to tighten, and waterproofed.

|

|

Since we now know, that this canvas will shrink by some 8 %, we now hose it over.

Once it dries, it will hopefully have got rid of some of the wrinkles.

|

|

Once the fabric is dry, it is waterproofed with a bitumen emulsion. This

particular emulsion is originally meant to be used for waterproofing house

foundations made of concrete.

|

|

Three coats of the bitumen emulsion, and one more lath ring to protect the outside

edge of the gunwale.

And the coracle is ready!

|

The paddle

Before the maiden voyage we still need a paddle. It seems, that not only the

actual coracle types, but also the paddle types, are river specific. I'm going

to mix rivers happily by making a river Teifi-kind-of paddle to my river

Severn-sort-of coracle. Why this? Because the Teifi paddle seems like very

easy to make, and delicate and slender indeed.

|

A "more correct" Severn paddle would probably be a "snow shovel" like the

one in the picture.

|

Judging by old photographs a Teifi paddle is something like this:

- The length is about the shoulder height of the paddler standing on the

ground. Something like 5' (150 cm).

- Out of this length, the blade makes up 1/3, the straight, round shaft another 1/3,

and the third 1/3 is a steadily widening, steadily thinning handle-shaft.

- The handle-shaft ends in a one-sided handle, shaped to fit in the palm of a hand.

- The blade is also one-sided, flat on the underside, convex on the top. Like a

wing profile.

- The blade gets thinner towards the tip.

- The blade tip is straight, rectangular.

- The top of the blade, at the shaft, is also rectangular.

A paddle like this is very easy to make out of a 5' length of some

1" x 4" straight grained plank of some lightweight wood.

|

I made mine out of a piece of aspen.

|

|

I sawed the edges of the shaft and handle, then hewed the shape of the blade

and handle to roughly correct shape, and finished the paddle with a

belt sander. First with 40 grit paper, then 80, and finally grit 100 by

hand.

|

Again, linseed oil is a suitable treatment. I did put some varnish onto the

tip of the blade, to prevent water from wicking up the end grain, and for

some mechanical protection.

The coracle on the water

|

This load is light to carry.

A coracle is so light, that it can be carried for miles.

Carrying my coracle along a roadside I noticed one more danger

that comes with a coracle.

People are not used to seeing coracles being carried.

One guy almost hit me wih his car: He could not steer, he was too busy

staring at me.

|

|

A coracle is paddled from the front with a "figure of eight" stroke.

|

You may get a better view of this by downloading a

coracle paddling (2.7 Mb) video clip here.

A coracle is tippy, so You better get into it while the bow touches

ground, and backwards, as in this

geting into a coracle (5.4 Mb) video clip.

Not so tippy, however, that it couldn't be rocked a bit.

And it spins and moves lightly in this other

paddling video clip (12.0 Mb).

The other possible stroke, "reaching forward" may not be

as effective as the "figure of eight". At least not

with a narrow paddle. Here You see some

"reach forward" paddling (3.4 Mb).

|

It was soon clear, why some paddles have a long narrow blade, some a short

wide blade. A long narrow blade is inefficient in shallow water. Only when the

depth is some 2' it comes to its own.

|

The two "old boys" with their coracles.

Note, that only one of them is wearing a life west ;-))

The length of the carrying strap is critical. If it's too short, it tends to

slip up around Your throat. Is it's too long, it tends to slip down around

Your chest.

Top of the page.

Back to main page.