Why does a wooden boat leak?

A boat leaks if it has a hole. Boats are not designed nor built

with holes. So a boat with a hole is broken.

If a wooden boat leaks, it is broken.

Why do people always talk about leaking wooden boats? Does a wooden

boat get broken more easily than other boat types?

Yes, because wooden boats are constructed in such a way, that they break

themselves if they are not surface treated and maintained properly.

How do they break themselves?

The theoretical swelling pressure of wood is calculated to be 1630 kp/cm2 /

24000 lbs/sqin. Pressures of about half of that have been measured. This is the

pressure that is exerted by wood if it swells in an enclosure where it

cannot expand.

Wood is an elastic material. A deformation caused by a force returns, when

the force is removed. Like a spring or a piece of rubber.

But only to a limit.

The pressure that causes a permanent deformation to the surface of

dry wood is in the range 10-100 kp/cm2 / 140-1400 lbs/sqin. This

pressure depends on wood species. The breaking pressure of spruce

and pine is about 30 kp/cm2 / 420 lbs/sqin. And this is for dry wood.

For fresh or wet wood the pressure limit is about half of the dry

wood value.

If You think of what happens on the cell pipe level, the pipes yield under

pressure and return to their original shape, when the pressure is relieved.

To a limit. When the pressure is high enough, the pipes crush and deform

permanently.

When wood swells, the swelling pressure may be up to 50 times the pressure

needed to break wood in a crosswise direction.

Let's do some "practical science" to see what this means in real world.

|

I hewed a piece of pine plank (floor planking, dried in a heated basement)

to exactly fit

the hole of an old roller bearing. The roller bearing will act as

"an enclosure where wood cannot expand". The diameter of the hole, and

thus also the width of the plank, is 80 mm (about 3 1/8").

|

|

"Swim and swell".

|

|

After four days of swelling the width of the plank end is 82 mm. It

has swollen by about 2.5 %.

Back to the basement to dry.

|

|

After four days of drying the plank is loose in the bearing hole.

Where the bearing has been the plank width now is narrower than it

originally was. It's now about 78.5 mm. That is, the plank was crushed,

broken.

You can just see a notch made by the bearing at the arrows.

|

In this little experiment the plank was crushed by almost the same amount

it would have swollen, had it been free to swell.

In a wooden boat the same can take place always, when a strake swells between

two other strakes. In a small area the same happens when a strake swells

between two fasteners on a frame. On a yet smaller area this happens under

each fastener head.

And what's that in practice? Let's see:

I made three "boat sides", small test specimens to imitate a side of

a wooden boat, using three different techniques.

Each specimen (let's call them "test boats" from now on)

consists of three full width strakes and one narrow.

Two of the strakes I fastened in the way I thought to be "right" (which

side out?), one in the "wrong way".

|

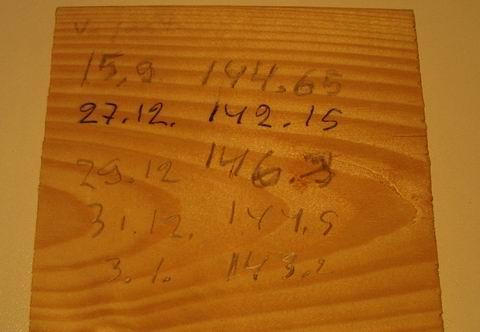

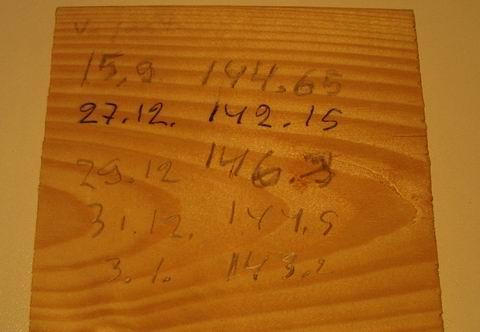

All "test boats" were made of dry 18 x 145 mm (3/4" x 6") spruce plank.

I left this loose piece as a control. Since I took the piece in from the

shed in september, it has shrunk by 1.7 % by the day after Christmas.

|

|

The first "test boat" is carvel. The two rightmost strakes are heart side

towards frame. This seems to be most correct, since the strakes are fastened

by the edges. The "frames" are of 21 x 45 mm (7/8" x 1 3/4") pine.

|

|

The second "test boat" is lapstrake with steam bent frames. Two rightmost

strakes are heart side in. Theses strakes can freely expand outwards

when cupping. The frames are of 20 x 20 mm (7/8" x 7/8") oak.

I planed the strakes only enough to get a flat seam width.

|

|

The third strake can cup freely also. There is plenty of room between

the strake and frame.

|

|

The third "test boat" is lapstrake with hewn frames. Here the srakes are

fastened in the middle, like used to be the practice on hewn frames.

Now it would seem

correct to fasten the strakes with heart side facing out. Two rightmost strakes

are thus fastened, the third, the leftmost, is fastened "the wrong way".

The frames are hewn out of pieces of pine floor planking.

|

|

I adjusted the frames to the strake cross sections. That is, I didn't

force the stakes to any flatter shape than they happened to be.

|

|

Everybody take a bath.

All "test boats" are of plain wood. No surface treatment of any kind.

They will absorb more water and swell more, and swell more quickly

than real boats would. This is really an accelerated test.

|

After two days swelling the test board has swollen by 2.9 %. It is impossible

to accurately measure the strakes in "test boats" now. Especially the

lapstrake readings are very "about". But still very surprising!

|

The strakes in the "carvel boat" have swollen, from left to right, by about

3.1, 0.5 and 1.6 %.

The middle strake, between the two others, has swollen very little. On the basis

of the "roller bearing experiment" I'd expect clear slits between strakes

once they dry out.

|

|

The measurements from the "lapstrake boats" are not certain, since they have

to be taken from the strake end. Anyway, it would seem that the strakes

have swollen by about 4.3, 3.0 and 3.6 %.

|

|

And on the hewn frame version by about

4.6, 2.9 and 3.4 %.

The "heart side in or out" doesn't seem to have any effect at this

point.

|

The measurements from the "lapstrake boats" were surprising. Measurements were

not accurate, nor could they be directly compared with "free plank" measurements.

But it was clear, that the strakes had been rather free to swell.

One often hears of how flexible a lapstrake boat is, but no one seems to

know what it is that flexes. I've seen a claim that it's the frames. The

frames would flex, since they are curved. But if that really would be the case,

a boat would roll up when strakes swell and frames bend.

Roll up, how so?

Let's take an example. Think of a boat with a beam of two meters (6' 8"). Let's simplify

things a bit, and assume the cross section of the hull to be a semicircle, and the

thickness of the planking to be 20 mm (7/8"). Think of the cross section now.

Since the beam on the boat is two meters, 2000 mm, the radius of the planking

semicircle is 1000 mm. And since the planking is 20 mm thick, the radius of the

semicircle of the frames is 980 mm. Correspondingly, the perimeter of the planking

semicircle is (pi x 1000) mm, the perimeter of the frame (pi x 980) mm.

And since both are semicircles, their (imagined) central angle is 180 degrees.

What happens, if the planking swells by 1 %? The planking perimeter grows to

(pi x 1010) mm. But since wood does not swell lengthwise, remember, the length

of the frame perimeter stays at (pi x 980) mm. If the planks stay on the frames,

and frames bend, the planking and frames still form a part of a circle, with

a difference of 20 mm in their radii.

But what are the radii? And what is the central angle?

Do some calculation, and You find out that if the 1 % swelling of the planking

is taken up by frames bending, the new radius of the planking will be about 650 mm.

That is, a boat with a two meters (6' 8") beam rolled up to a boat with a 1.3 m (4' 4")

beam. And the central angle would be about 280 degrees. Three quartes of a circle.

Had the planks swollen by 2 % the boat would have rolled up to a pipe with a

diameter of just below one meter (3' 4").

Nothing even approaching this takes place in the real world. So it must be something

else, not the frames, that flex.

The "dry-wet" pictures above would seem to show, that the flexible part

in the stucture are the rivets, that fasten the planks to the frames.

And a part of the flexing takes place within the planks, that assume

a clear S-shaped cross section.

The picture seems to hint, that every plank takes support on the right

edge at the root of the rivet, pushing the top of the lefthand side

rivet to the left. This way each rivet seems to bend to the left, and

every plank twists to a S-cross section.

|

Every fastener head has crushed the wood clearly.

|

Back to drying.

|

To rule out a possible "overdrying", I checked the result when the reference

plank was still 0.7 % swollen from the start of the test.

|

|

The carvel boat would leak like a sieve. Note the matchsticks between

the planks.

The "roller bearing phenomenon" struck the carvel boat really badly.

The same phenomenon also hit all the fasteners. Tha planks were all loose, since

the tree under the screw heads was crushed.

One could say the carvel boat was badly broken by a single swelling.

|

|

The clinker boats developed leaks, too. Not as bad as the carvel, though.

|

|

A gap gauge shows the slit between the plank edges to be 0.3 to 0.6 mm.

This seems to be mainly due to wood having crushed under the rivet heads.

|

A wooden boat breaks herself, because her structure does not allow wood

to swell freely.

When wood is not allowed to swell freely, it breaks internally, gets

permanently crushed. When it dries and contracts, it will no longer fill

the original space. There will be slits around.

Or if the edges of wood are fixed, the slit will appear at a weak point,

somewhere in the middle of the plank.

The common belief, that a wooden boat "breaks by DRYING" is wrong.

A wooden boat breaks by SWELLING, the drying only makes the breakage

visible.

Many structures in wooden boats are against the nature of wood. One

could almost say many stuctures are "wrong".

A lot of harm caused by wrong structures can be compensated for by

proper surface treatment and proper care. Both should aim at reducing

the changes in wood moisture content, and thus changes in wood

dimensions.

Proper care consists partly of keeping the surface treatment in good

condition, but also of maintaining a balanced wetting-drying cycle.

The cycle should not drift in either direction.

The Scandinavian experience shows, that a one year cycle (half a

Year in water, half a year in a shed) is just manageable. With

tedious surface treatment.

Life is probably easier in the areas where waters don't get frozen.

Where boats can stay in water all the time, or come in and out

of water daily, all year around.

Preface

What is a "wooden boat"?

Structure of wood

Moisture behaviour of wood

Why does a wooden boat leak?

Surface treatment of a wooden boat

The "correct" construction of a wooden boat

Top of the page.

Back to main page.