The construction of a typical wooden boat is not so "wrong" that it would not last for decades with proper surface treatment and care. But it might be fruitful to think of ways to do it better. It shoud be possible to build a boat that would tolerate moisture changes and stay undamaged without any surface treatment at all.

Or maybe this is just unfounded optimism :-)

Wooden boat are built in two principally different ways, carvel and lapstrake. People tend to see the difference only in ways of working, or difference in appearance. But the difference is deeper than that.

Carvel and lapstrake are two different approaches to build a boat that tolerates wood swelling and shrinking without breaking or developing leaks.

Both types could be built to tolerate moisture produced dimensional changes. But the builder must honor the principal differences in the two different techniques:

In a carvel built boat each stake lives a life of its own. There is a slit between strakes. The width of the slit changes as the widhts of the planks change, due to changes in moisture. There has to be some kind of flexible sealing in the plank seam. The sealing has to be so flexible, that it fills the slit at its narrowest and at its widest.

In a lapstrake boat the whole hull skin is one piece, there is no slit between strakes however the skin swells of shrinks. The other structures (frames, stems...) have to flex in such a way, that the hull skin can swell and shrink freely.

The strakes and slits between them shall be dimensioned in such a way, that when the strakes are most swollen, they don't press (=crush) each other but the flexible seal between them is pressed to its thinnest.

Each strake can be fastened to each frame and stem with only one fastener.

Strakes should be radially sawn to minimise swelling and cupping.

When the strakes are at their narrowest, when they are dry, the flexible seal must still stretch to fill the slit between strakes.

Strakes shall be narrow to stay put with only one fastener per frame, and to keep the slit changes within the limits of seal elasticity.

And the fasteners shall be more flexible than nails or rivets, in order to prevent wood from crushing under the fastener head. Possibly a flexible "pillow" between each strake and frame.

Boats are not consturcted like this in practice.

The golden era of building lapstrake boats in line with the nature of wood was during the Viking age, sometime around years 800 to 1000.

Lots of details of buried and wrecked Viking ships and boats have been documented. The ways of construction differ from modern methods. Some seem strange, some even misguided.

Why the boats were constructed the way they were constructed has been given surprisingly little thought. It seems, that in the archaeology science it is only customary to ask "what?", but not "why?"

But since I'm not an archaeologist, I may ask "why?", and work upon an

answer.

Here's one:

The purpose of the special construction details in Viking ships was to prevent the ships from breaking, by allowing wood swell and shrink freely.

At least three special construction details found in Viking ships could be explained by good understanding of wood moisture behaviour:

Not all details can be found on all ships, however.

The frames of many Viking ships don't stretch from sheer to keel to sheer in one piece. The frames are more like a set of frame stubs supported by a star like lattice.

The frames of Skuldelev 3 and Skuldelev 5 ships were contructed this way.

The star like support lattice (red) consists of the seat, a floor support beam, two vertical supports between them and a single vertical support between the floor beam and the keel frame stub (yellow).

There is a frame stub at every point of the star. At the seat ends (pale blue), at the floor beam ends (pale green) and at the lower end of the lower vertical support (yellow).

The keel (violet) is NOT attached to the lowest frame stub (yellow) at all. The other frame stubs are attached to planking by lashings or a single nail and lashings. But the frame stubs are not attached to each other.

The construction is solid as far as pressure against ship sides is considered. Much firmer than an ordinary frame would be.

Yet it is very flexible in the direction where the ship planking swells and shrinks. Swelling and shrinking forces are opposed only by bending stresses of the seat and floor beam.

In a modern boat hull strakes meet the stems at more or less right angles. The ends of the strakes split, because the plumb attachment to the stem does not yield with stakes swelling or shrinking.

In a Viking ship the last stakes near the stems were carved out of naturally curved wood. This way the stakes meet the stems with grains almost parallel.

The stem and strake both swell and shrink in the same direction - no stresses in either member.

Viking ship strakes were lashed to frames with sinew or spruce root lashings (tree and iron nails were used, too, of course).

Any modern man would make a strake lashing something like this. Drill holes to the starke, run the lashing through the holes, around the frame and back through the holes.

How would a lashing like that behave when the strake swells? It should allow the stake to slide along the frame, to allow the strake swell freely.

But the strake does not swell just widthwise. It also swells thicknesswise. Tightening the lashing, making the stucture stiff just when some slackness was needed. Well, it will be slack when the swelling stake rips the lashing open ;-)

But Vikings used a lashing something like this.

When the strake was hewn lumps of wood were left on the strake on either side of each frame location. Holes for the lashings were drilled only through these lumps, not the whole strake.

An extremely laborious structure. What's the point?

When the strake swells, the lump on the inner surface swells inward, loosening the lashing, letting the strake swell and slide sideways.

And of course, it is a good idea not to make holes in Your boat hull. It may also be nice to be able to renew a broken lashing underway without going under the ship ;-)

If structures like these are good, why have they been given up? Why did they not live until today?

I suppose the "quicker, more, faster" came along. Constructions described above are laborious, especially without the use of electric tools. (So why did Vikings not just start using electric tools? ;-)

Vikings might see carvel buils ships with their continuous frames in the Mediterrenean. "Hey, that's the way to build more ships quickly. More ships, more conquests. Let the old grayhead boatbuilders keep their 'proper ways of building'".

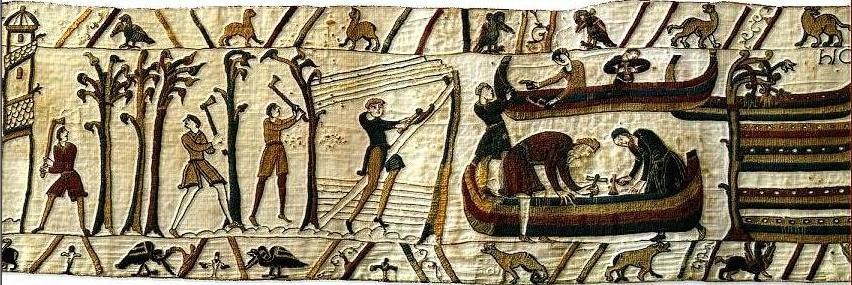

The only known documet describing Viking ship construction, the Bayeuxin tapestry gives a hint of the state of ship building in the end of the Viking era.

The tapestry describes the Norman attack perparations before the battle of Hastings in 1066. There was a great haste (hence the name Hastings? ;-). A great navy was needed yesterday. 600 ships were needed to carry 10-12000 men and 2500 horses across the English Channel. The longevity of the ships was of no consequence.

Boats and boat construction have always been improved. But based on what?

Based on what father did.

Before the beginning of the 20th century there was hardly

such a thing as "written history". Builders only knew the ways just before them, only

the ways of the previous generation. No one could see back beyond that. Nor could anyone know

how things were somewhere else.

Now that history is known we can play a mental game, that was never before possible: We can jump back a thousand years, and take a construction detail. And start improving that detail with modern tools and materials. We are sure to end up with something totally different than what the thousand years of generation to generation development ended up with. Possibly something better!

Taking the structures of a Viking ship as a starting point it could today be possible to design a wooden boat, that would be long lasting even with bad maintenance.

A mental game like this was never before possible. But does anyone play the game?

These guys seem to have played some :-)